The team at Eleri combines extensive first principles mechanical analysis of battery processes to the wealth of knowledge in cell manufacturing to improve Safety, Life, and Performance of lithium-ion batteries for vehicular applications.

Since 1991 when Sony commercially introduced the first lithium-ion cell (18560 form factor), advances in cell active and non-active materials, electrolytes, cell design, cell manufacturing processes have increased energy density, power, life, and lowered cost.

Eleri, through intelligent mechanical design, complements and enhances these advances.

Improved Safety

Improved Life

Improved Performance

What we do different

Many electrochemical processes, aging mechanisms, and safety issues in batteries are directly related to the mechanical stresses, loadings, and failure mechanisms under everyday cycling loads or accidental abusive overloading.

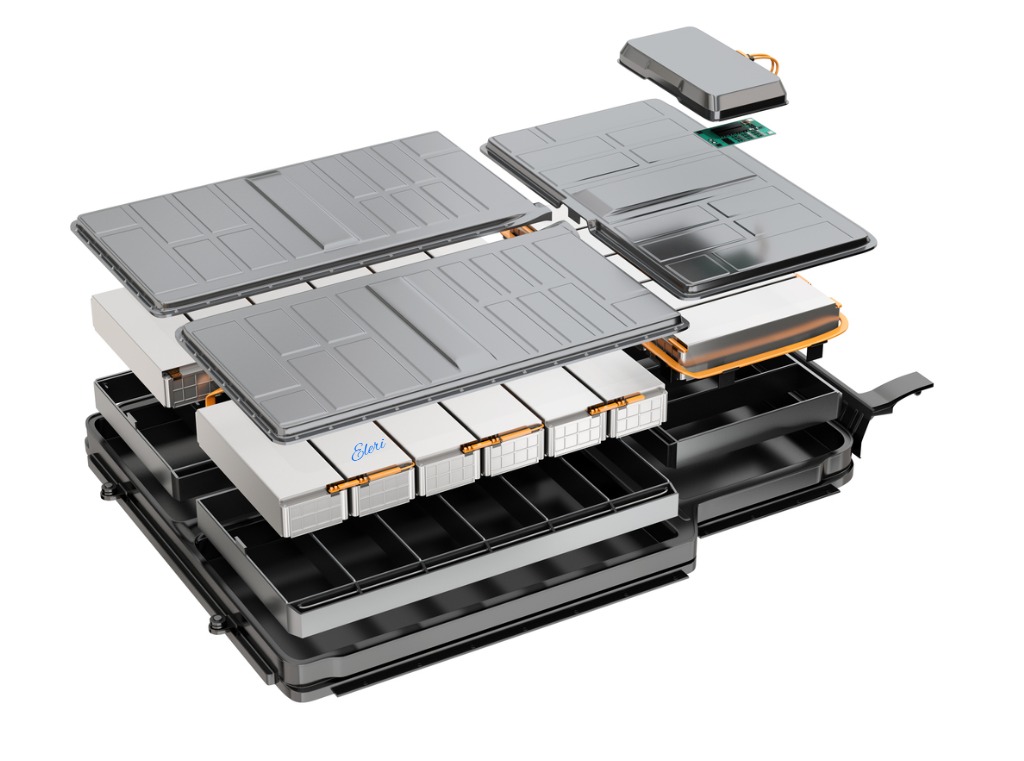

Eleri improves cells functions starting at the scale of battery electrode architecture to the design of exterior casings. Improvements at cell level will ultimately reduce the cost and weight of protective structures at pack level, further contributing to improvements in energy density, range, and cost of electric mobility.

This effort integrates materials science, electrochemistry, cell and pack design with structural mechanics and vehicle dynamics.

In everyday operation of batteries, the overall system mechanical forces arise from

- Charge/Discharge: lithiation and delithiation causes volume changes in the active materials

- Cell Packaging: Cell containers, i.e., cans, constrain the volume expansion exerting force on the electrodes/jelly roll. For pouch cells module/pack components can also play this role.

- Driving: Acceleration/deacceleration exert forces on the cell. Crashes generate the most extreme forces through deformation of the car and pack.

Eleri’s Novel Structure

At the cell level improves tolerance of cells to the above mechanical forces. The important benefits include:

- Improved mitigation of cycling volume changes and associated stress on the cell

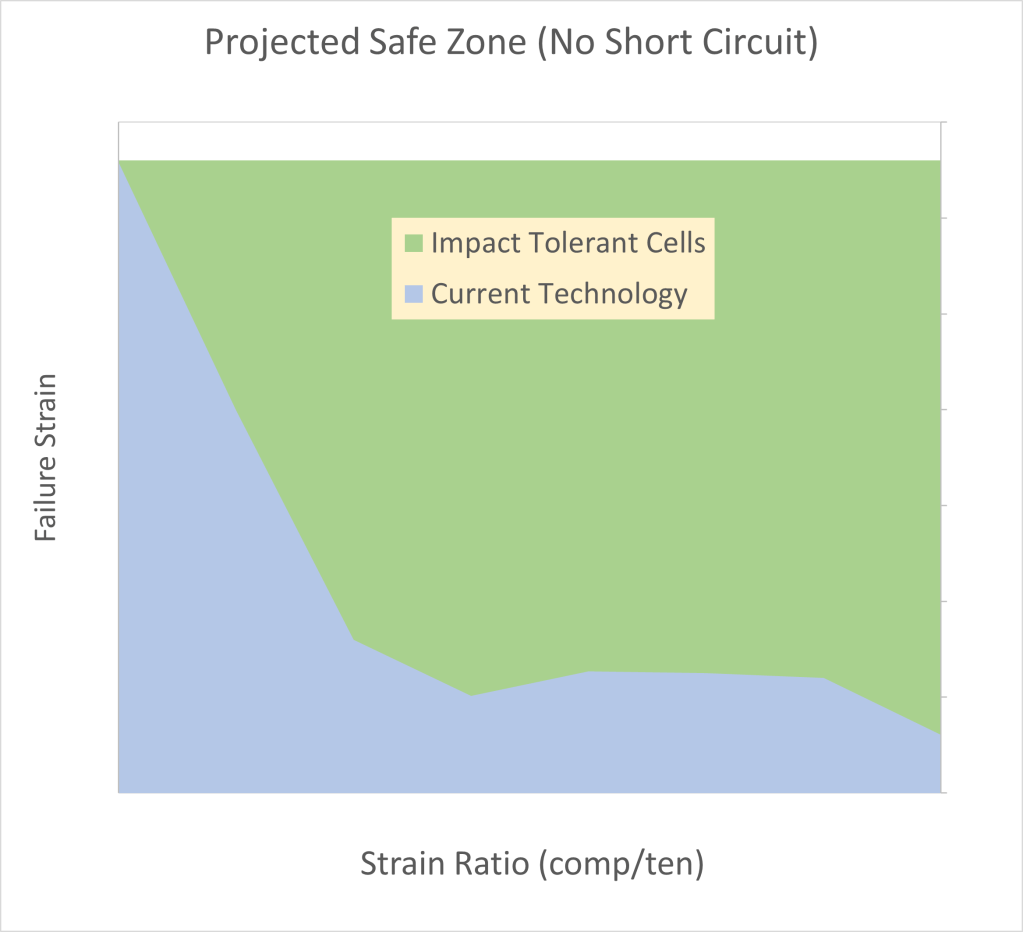

- Reduced tendency to develop internal shorts which can lead to thermal runaway

- Reduction in the weight, volume, and cost of pack and vehicle design elements to protect the cell, thereby improving vehicle efficiency and range and reducing cost

Mechanical load and impact tolerant cells of Eleri reduce detrimental changes in the jelly roll thereby improving safety, performance and life of the cell.